From condiment set manufacturing to the

digitalization of Industry 4.0.

Request Now

Precision Products from Brüninghaus & Drissner

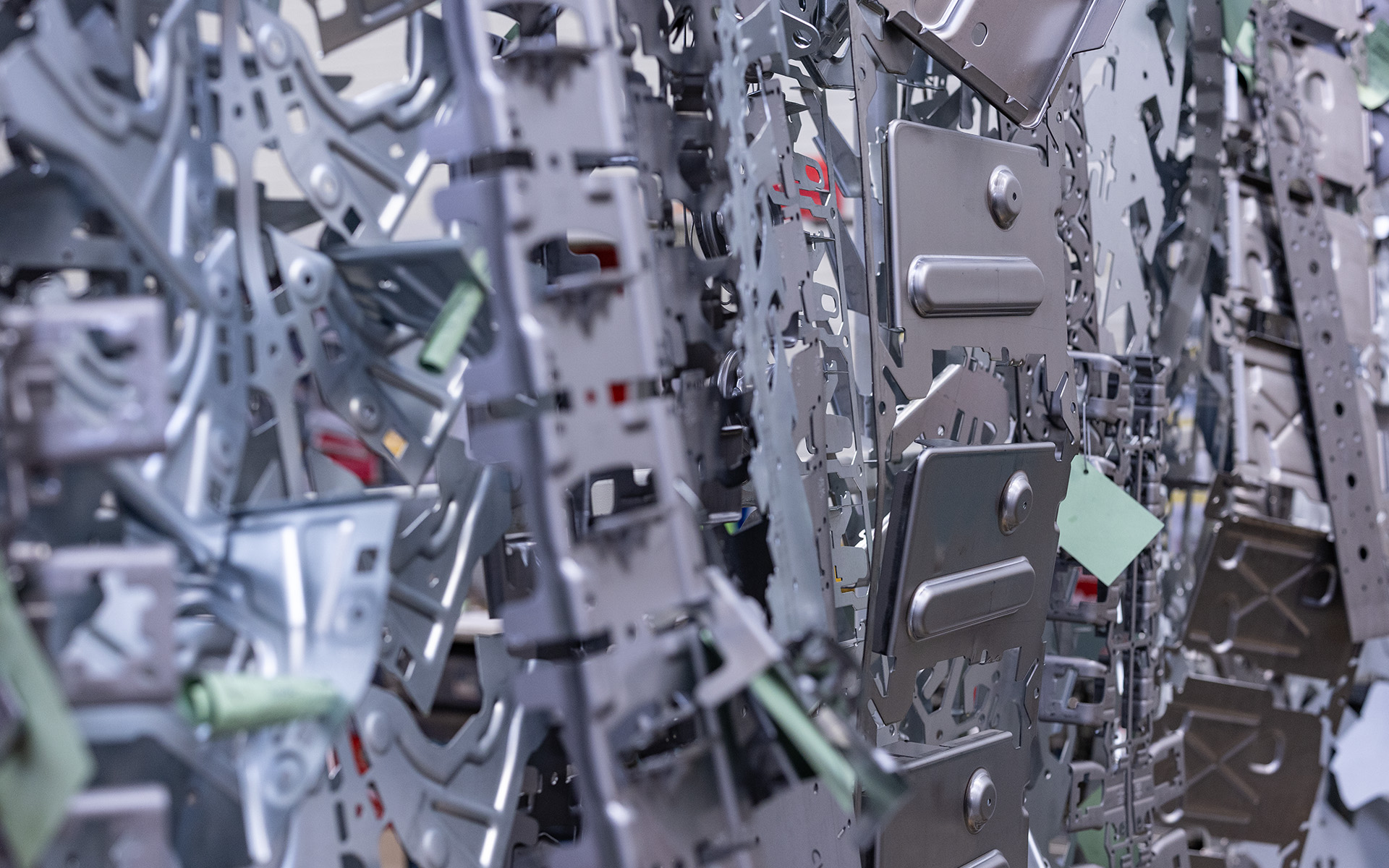

Our company is an internationally active supplier to the automotive industry, specializing in the production of stamped and formed parts, as well as welded assemblies. With our dedicated team of 110 employees, we produce up to 300,000 parts daily and process up to 1,000 tons of material monthly. Our core competencies lie in stamping and forming technology, welding technology, and the production of welded assemblies.

As a global supplier, we deliver to over 200 locations worldwide, including sites in Germany, France, England, Spain, Czech Republic, South Korea, Mexico, and Brazil.

Our global logistics networks and efficient supply chains ensure that our products arrive at our customers’ locations on time and in the best quality.

Our highly qualified employees are the backbone of our company. Their expertise and dedication help us meet the stringent requirements for our products daily. Our goal is to continually invest in employee training and cutting-edge technologies to remain a leading supplier in the industry.

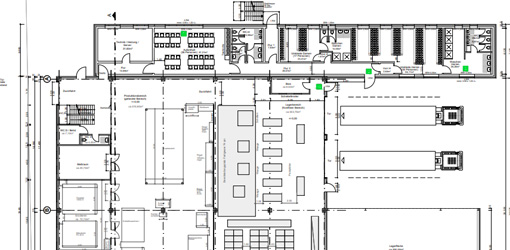

In 2024, we will reach a significant milestone with the move to our new site, which will offer state-of-the-art infrastructure, optimized production conditions, and room for future expansions. This enables us to further expand our production capacities and respond even more flexibly to our customers’ needs.

With our strong core competencies, upcoming expansions, and international reach, we are well-positioned to meet the growing demands of the automotive industry and other forward-looking sectors, cementing our role as a reliable and innovative partner.

""We are a high-performance

family business.""

Our focus is on the customer: We listen, understand your needs, and offer customized solutions for every challenge. As a family-run company, we place great value on respectful cooperation and a friendly work environment where every employee counts.

Trust in our experience and commitment –

together we will make your projects a success!

Marc-Oliver and Tanja Köhler,

Management

Our Guiding Principles PDF Download (German)

Customer Focus

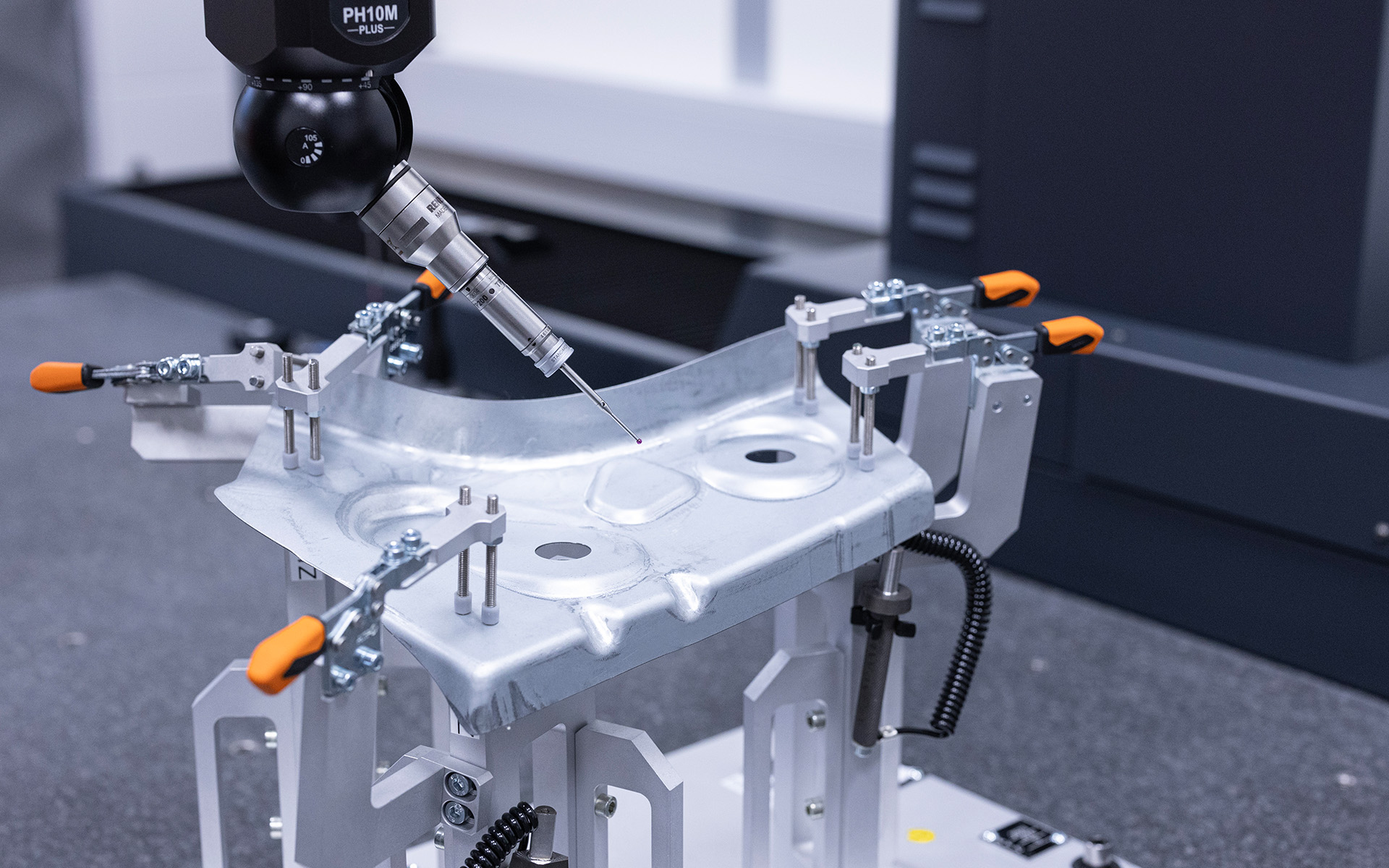

Our company goal is to create customer value. Every employee recognizes the customer as the focal point of our efforts. Only the highest quality and full compliance with customer requirements will secure our success and give us a competitive edge.

Reliability

We pursue a consistent zero-defect target in our services and aim for 100% on-time delivery. The necessary and economically viable measures are taken to achieve these objectives.

Continuous Improvement

The continuous improvement of all processes is a central part of our operations. We regularly measure quality, environmental, and energy performance, as well as the cost-effectiveness of our processes, using appropriate metrics. We evaluate the results and implement corrective measures when deviations occur to ensure success. We focus on innovation and efficiency improvements and provide the necessary resources. We also expect this commitment from our suppliers.

Employees

Our employees are the key to high quality. Through targeted selection, comprehensive onboarding, continuous training, and raising awareness in quality, environmental protection, energy management, and occupational safety, we ensure that our employees are always qualified and motivated. These measures not only ensure their technical competence but also promote their awareness of sustainable actions and safe work practices, fostering a dedicated and responsible workforce that significantly contributes to our success.

Accountability

Achieving our quality goals is only possible through the accountable actions of all employees, working collaboratively with management. Each individual is responsible for preventing hazards to people and the environment and strictly complying with regulations and laws regarding labor, health, environmental protection, and energy management. Additionally, we regularly discuss potential incident scenarios with our employees to ensure we are optimally prepared to respond quickly and effectively. Through this proactive and collective approach, we ensure our high standards are met in all areas.

Sustainability

We contribute to society by preventing environmental harm and continuously improving our environmental performance to conserve resources. We are committed to sustainable resource management and take responsibility for future generations. Compliance with standards, regulations, laws, and environmental and energy-relevant requirements is just as self-evident to us as our binding obligations.

Our management system at both locations meets the requirements of IATF 16949 and exceeds the standards of ISO 14001.

Our environmental performance is communicated to employees via the intranet and to external interested parties upon request.

Processes & Services

The health and safety of our employees is our highest priority. Therefore, we design our processes with a focus on health and safety, minimizing any harmful effects on the environment.

The resulting economic efficiency from our policy guarantees secure jobs and the future of our company. Our quality policy is accessible at any time via the internet and is communicated to employees and other stakeholders.

Historical Timeline

Machinery

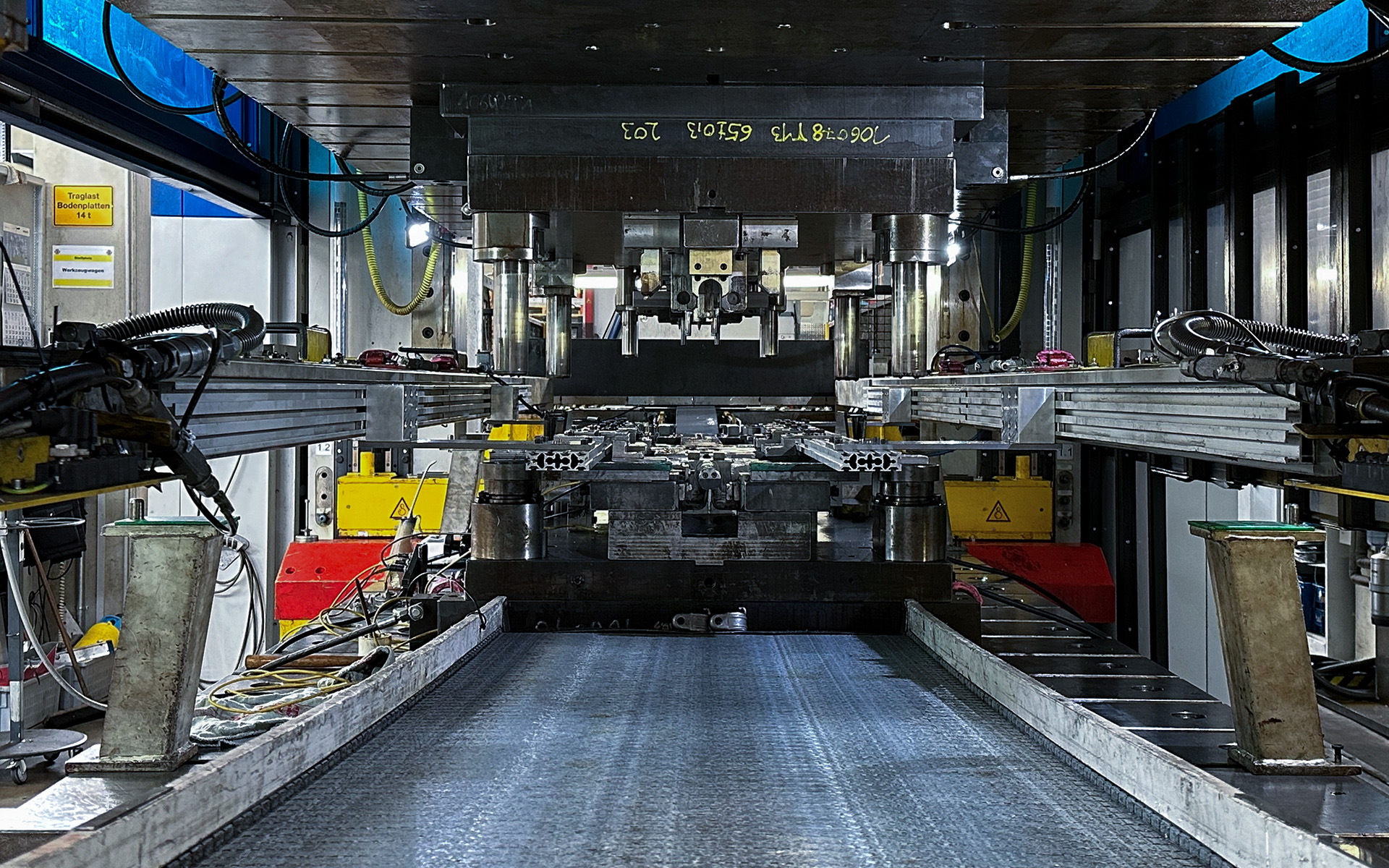

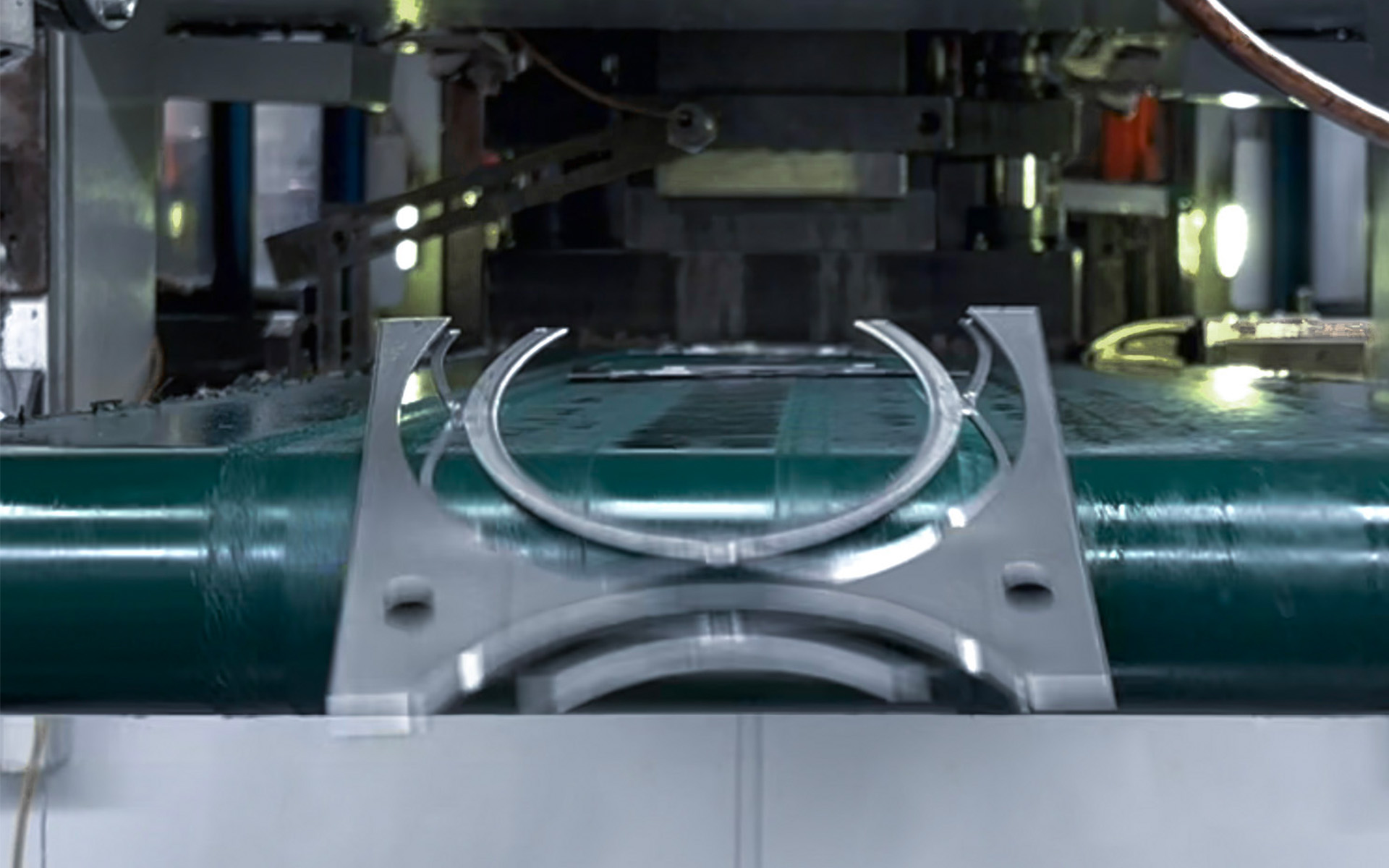

Our machinery is designed to meet a wide range of customer requirements and specifications. This includes transfer presses, progressive dies, and innovative stamping presses with impressive press forces ranging from 1,250 kN to 6,300 kN. These precision machines are capable of processing material thicknesses from 0.5 mm to 10 mm and strip widths up to 1,300 mm, providing high flexibility, reliability, and accuracy in production.

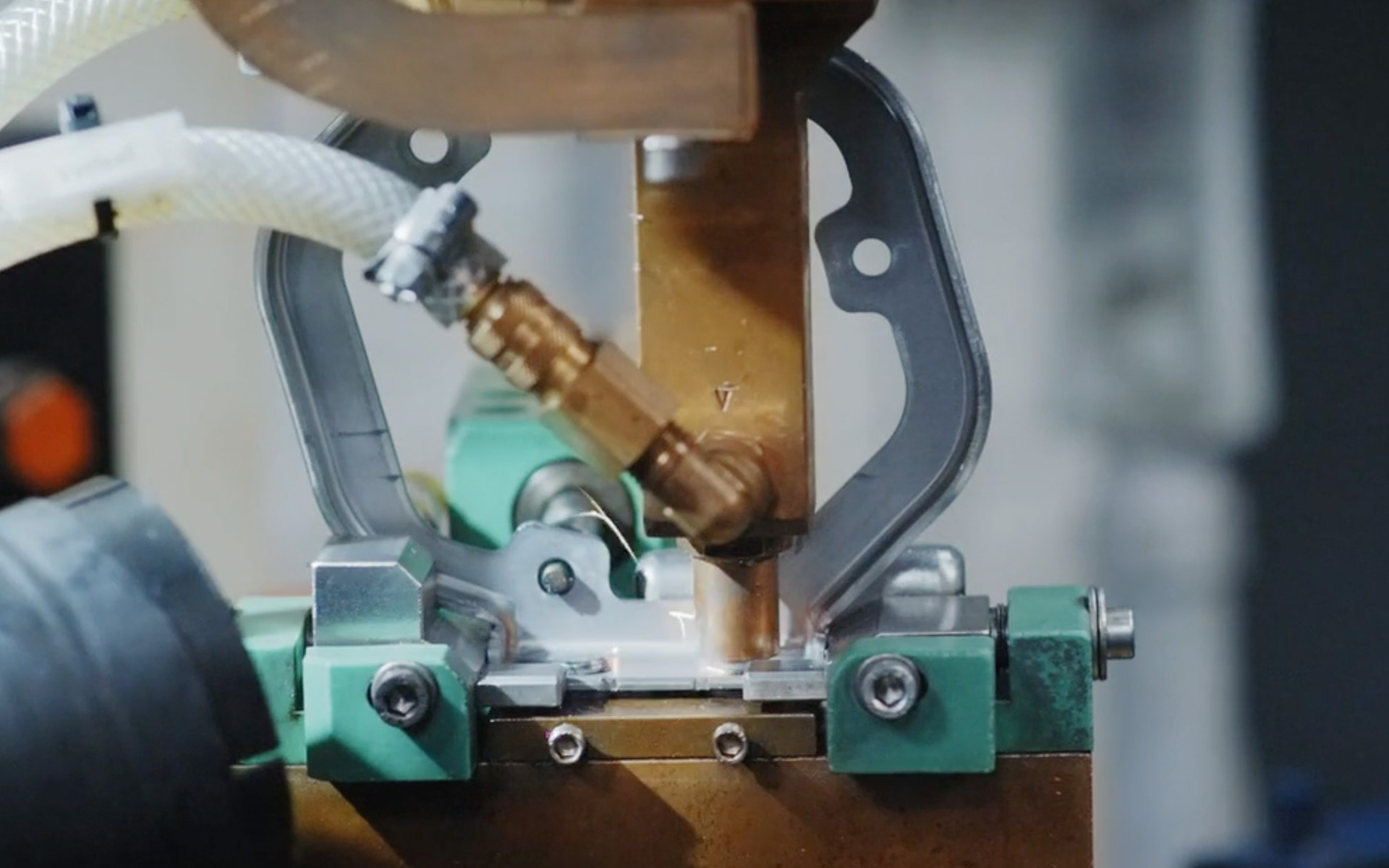

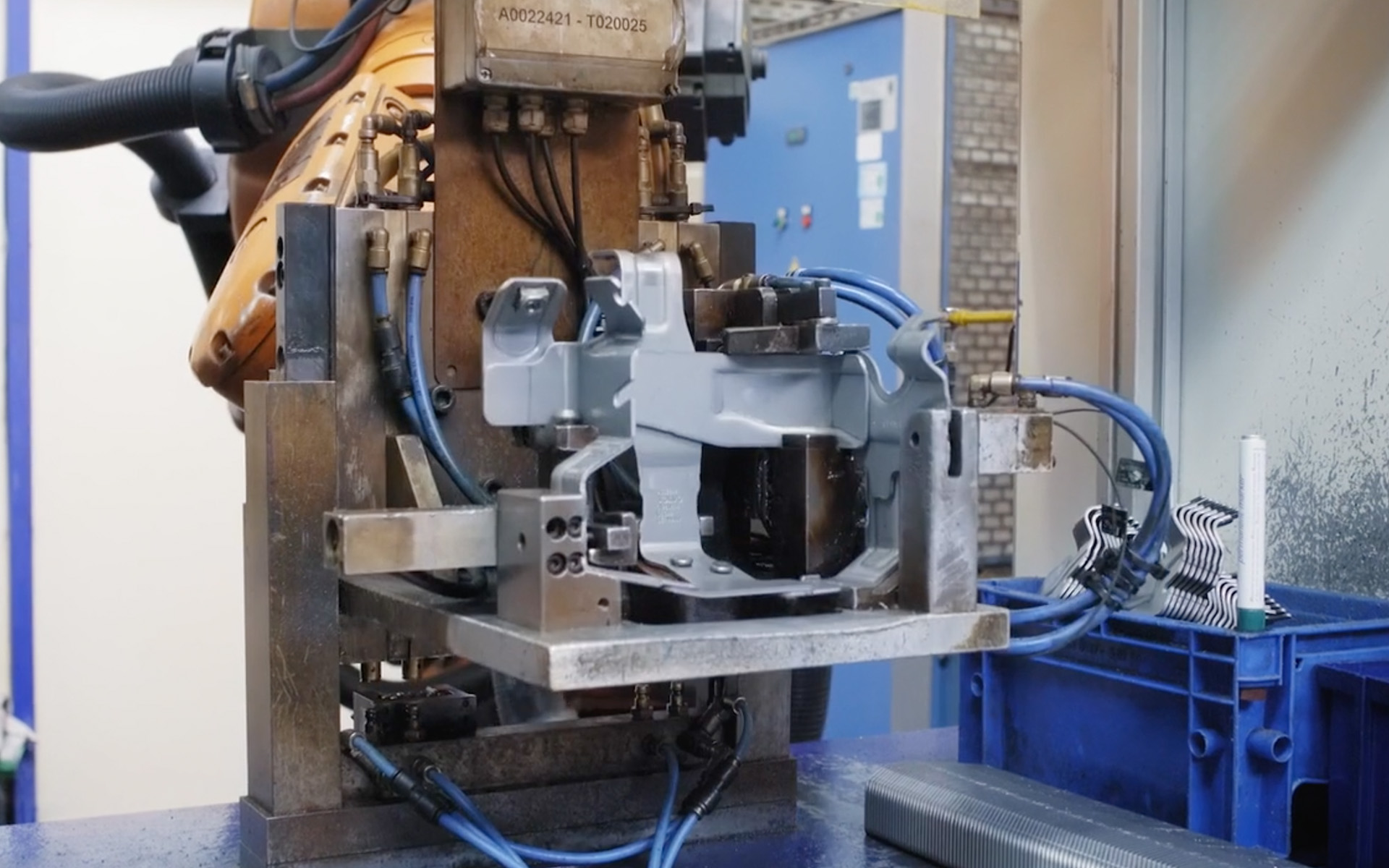

Our modern machinery is complemented by various welding systems, including resistance welding presses, MAG welding systems with capacities from 50 to 200 KVA, spot and projection welding machines, and modern 6-axis welding robots. These machines can process material thicknesses from 0.5 mm to 12 mm.

Particularly noteworthy are our fully automated 6-axis robots, which significantly enhance the efficiency and productivity of our manufacturing processes through their high application speed. These robots are capable of performing complex welding tasks with the highest precision and repeatability, ensuring the high quality standards our customers expect.

| Machine | Lifting height in mm | Installation space hight in mm | Tablebar height in mm | Material width height in mm | Maximum inlet in mm | Base area tool in mm | Coil- diameter in mm |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | ||||

| Raster 125 to | 5 | 120 | 385 | 130 | 240 | 130 | 190 | 250 | 820x500 | 1500 | |

| Raster 180 to | 10 | 150 | 450 | 600 | 160 | 300 | 120 | 175 | 320 | 1500x900 | 1900 |

| Raster 200 to | 30 | 160 | 450 | 200 | 370 | 100 | 200 | 250 | 1100x580 | 1600 | |

| Raster 180 to | 20 | 160 | 450 | 100 | 400 | 170 | 400 | 450 | 1900x1100 | 1700 | |

| Raster 250 to | 30 | 150 | 600 | 200 | 400 | 100 | 210 | 400 | 2000x1250 | 1720 | |

| Beutler 300 to | 40 | 315 | 335 | 650 | 100 | 400 | 0 | 200 | 500 | 2200x1200 | 1500 |

| Schuler 400 to | 40 | 315 | 435 | 750 | 200 | 500 | 0 | 300 | 800 | 3000x1300 | 2000 |

| Schuler 630 to | 80 | 400 | 700 | 1000 | 300* | 600* | 200 | 450 | 1300 | 4000x1800 | 2000 |