Fixture Construction

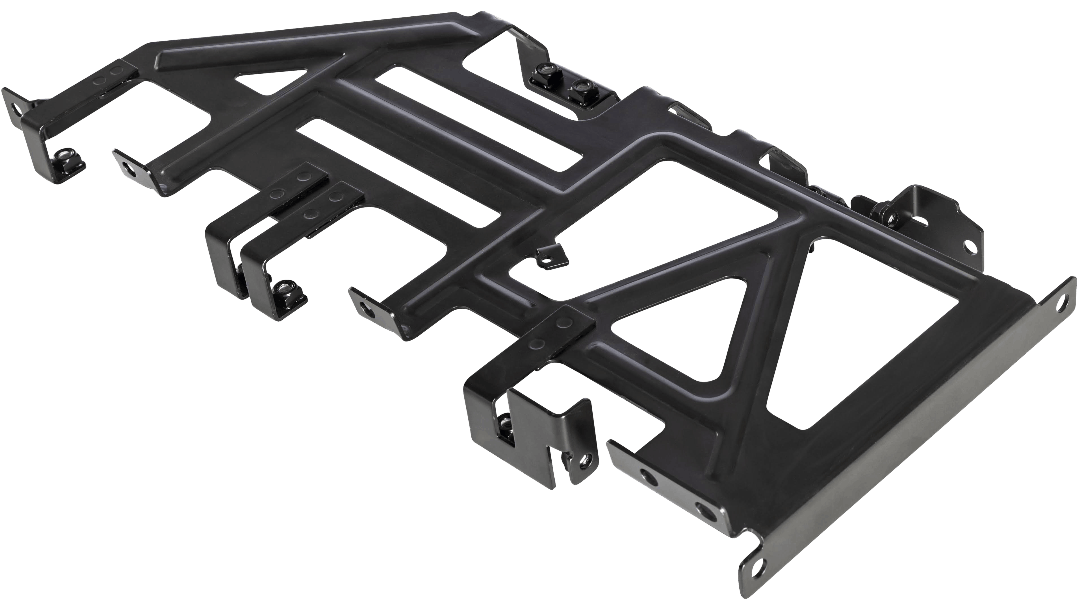

Fixture construction involves a series of specialized services for the development and manufacturing of custom fixtures. The process begins with the design and engineering of fixtures, using 3D models and technical drawings. Prototypes are created and tested to validate and refine the design.

Manufacturing is performed with precision using CNC machining centers and other machine tools, utilizing high-quality materials. Afterward, the fixtures are assembled and put together, incorporating components such as clamping systems and tool holders. Adjustment and calibration ensure the precision and repeatability of the fixtures, supported by thorough testing.

Maintenance and upkeep guarantee the smooth operation of fixtures, while quality control ensures all technical specifications and standards are met. Technical documentation includes drawings, assembly instructions, and maintenance records, with design changes and test results documented accordingly.

Technical consultation and training are offered to train personnel on fixture handling and operation. Research and development efforts focus on improving existing technologies and integrating new processes. These comprehensive services ensure that fixtures are used efficiently and accurately in stamping and forming processes, significantly improving production quality and efficiency.

DIPL.-KFM. JÜRGEN DRISSNER

We offer you:

Fixture Design

- Design and engineering of fixtures for specific manufacturing processes, such as stamping and forming fixtures.

- Creation of 3D models and technical drawings for fixtures.

Prototype Construction

- Manufacture of prototypes for new or modified fixtures to verify design and functionality.

- Test runs to adjust and optimize the fixtures.

Manufacturing

- Precise manufacturing of fixtures using CNC machining centers, milling machines, lathes, and other production tools.

- Use of high-quality materials to ensure stability and durability of fixtures.

Assembly and Setup

- Assembly of individual parts into fully functional fixtures.

- Integration of components such as clamping systems, guides, and tool holders.

Adjustment and Calibration

- Fine-tuning and calibration of fixtures to ensure precision and repeatability.

- Testing for functionality and adjustment as needed.

Maintenance and Repair

- Regular maintenance and inspection of fixtures to ensure smooth operation.

- Repair and readjustment in cases of wear or damage.

Quality Control

- Execution of quality checks to ensure compliance with technical specifications and standards.

- Inspection of fixtures for dimensional accuracy, functionality, and stability.

Documentation

- Creation and maintenance of technical documentation, including drawings, assembly instructions, and maintenance logs.

- Documentation of design changes and test results.

Consultation and Training

- Technical consultation on the selection of appropriate fixtures for specific manufacturing tasks.

- Training of personnel in the handling and operation of fixtures.

Research and Development

- Development of new fixture technologies and concepts to enhance manufacturing processes.

- Research projects to integrate new technologies and methods.