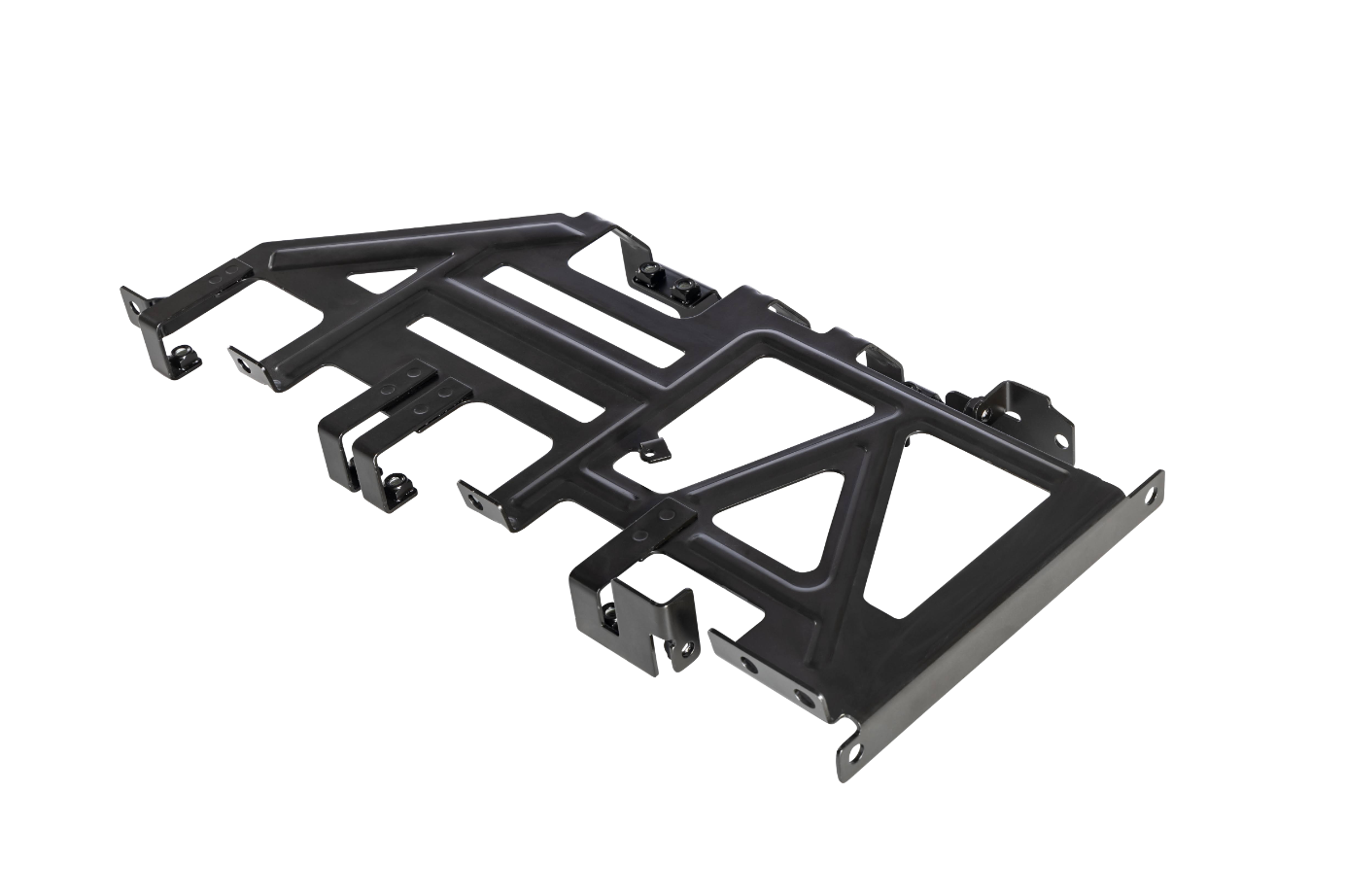

Quality assurance

At Brüninghaus & Drissner, quality assurance plays a key role in ensuring the highest precision and consistent product quality. Using state-of-the-art measuring and testing technologies, we monitor all production steps to detect defects early and minimize rejects.

Our quality assurance encompasses seamless process control, from incoming goods inspection through continuous in-process control to final inspection of the manufactured components. Using optical, tactile, and digital measuring methods, we ensure that all

Products meet the required tolerances and standards.

Thanks to our IATF 16949-certified quality management system, we guarantee the highest standards in manufacturing. Through regular employee training and close collaboration with our customers, we continuously optimize our processes to deliver precise, economical, and durable stamped and formed parts.

DIPL.-ING. MARKUS NICKOLAI

Head of Quality Assurance / TrainingWe offer you:

Incoming goods inspection

Ensuring material quality before production begins

In-process control

Continuous monitoring during production

Final inspection & documentation

Detailed inspection protocols and measurement reports

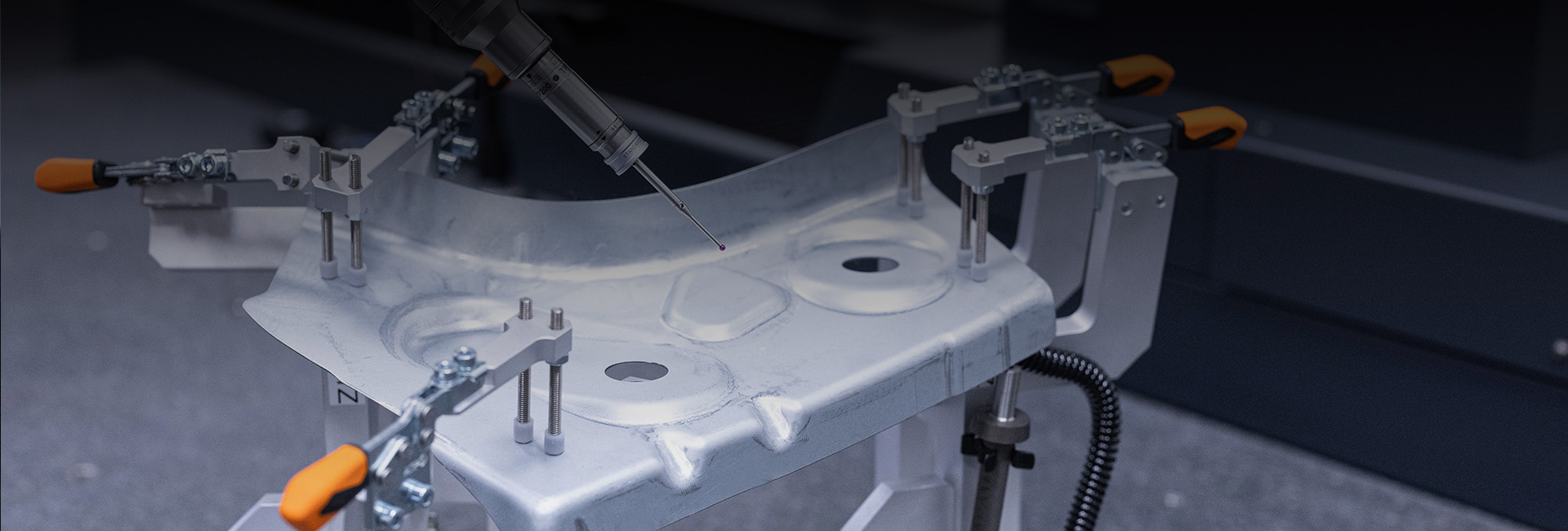

Optical & tactile measurement methods

High-precision measurements to ensure tolerances are met

3D metrology & digital testing methods

State-of-the-art technology for precise analyses

Error monitoring & root cause analysis

Rapid identification and correction of deviations

Certified quality management

Production according to IATF 16949 and other standards